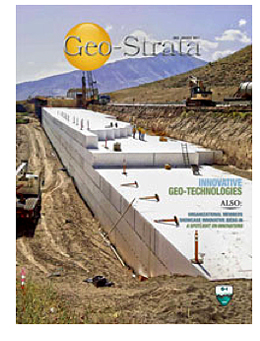

Topaz Bridge project, foam fill featured in ASCE magazine

A project that uses unique fill material on the approaches to the new Topaz Bridge is featured on the cover of Geo-Strata magazine.

A project that uses unique fill material on the approaches to the new Topaz Bridge is featured on the cover of Geo-Strata magazine.

The publication is produced by the American Society of Civil Engineers and focuses on unique construction techniques.

Construction of a new Topaz Bridge over the Union Pacific Railroad and Portneuf Marsh Valley Canal east of McCammon incorporates large foam blocks as fill material for the bridge approaches, explains Joe Pihlaja, an engineer with District 5.

Soil under the west approach is unstable because of high water content. Weight from conventional construction would make the fill susceptible to settlement and compromise the highway.

So engineers turned to high-density foam, called Expanded Polystyrene (EPS) or "Geofoam,” as an alternative – the first such application in Idaho. The Utah Department of Transportation used a similar approach on an Interstate 15 project before the 2002 Olympics.

As the four-lane bridge takes shape nearby, subcontractor Scarsella Brothers of Seattle began placing high-density foam blocks as a lightweight fill for the west bridge approach. Most blocks are about four feet wide, four feet high, seven to 14 feet long and weigh between 200 and 400 pounds. Conventional fill weighs about 100 times more, Pihlaja says.

For a recent Transporter story on the bridge project and use of high-density foam go to:

http://itd.idaho.gov/transporter/2010/090310_Trans/090310_D5FoamFill.html

Published 9-2-2011