D-3 introduces two innovative efficiency projects

In these tight economic times, ITD strives to find new and innovative ways to improve efficiency and stretch available funds. District 3 in southwest Idaho has introduced a number of initiatives that help ITD achieve the most with available funding. Among them are:

D-Tec traffic detection

In May, District 3 experimented with a new traffic-detection system at the Northside Boulevard intersection that serves the westbound on-ramp traffic heading onto Interstate 84 in Nampa.

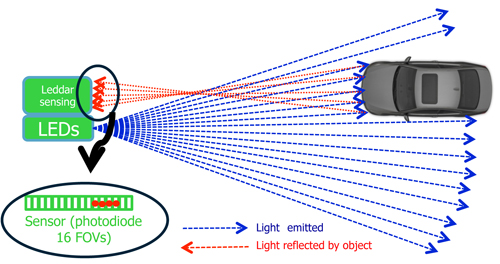

New technology using LED illumination (based on the time of light for detection and range-finding for 16 sensors within the Field of View) was used by D-Tec, a traffic detection system by LeddarTech.

Traditional loops in the pavement required too-frequent replacement. Heavy trucks going to and from the nearby sugar beet processing plant were prematurely deteriorating the roadway surface. Loops would not last more than a year, according to D-3 estimates. Using signals based on video detection also was problematic because of “fog,” created in part by the factory. The D-Tec system claims not to be affected by fog and ambient street lighting.

If D-3 traffic engineers are not satisfied with the performance of the new D-Tec equipment, the bid allows replacing it with a video-detection system. The eastbound ramp at that location is based on video-detection, so the interchange can serve as a “controlled” lab experiment.

The LeddarTech system costs about $5,500 per detector. Video-detection cameras cost about $4,000 each. Loops are significantly less for a small intersection, but the cost difference narrows because of the multiple lanes at busier intersections. Additionally, if pavement conditions were such that ITD needed to resurface the approaches, then D-3 might find the loops become more expensive than D-Tec.

The cost benefit for the D-Tec system might come from its longevity, performance in fog and lower maintenance since lenses on a video-detection system require frequent leaning.

Idaho 52 SAFLEA

Idaho 52 SAFLEA

In August 2010, District 3 used a new treatment method on a section of Idaho 52 near Emmett that needed surface repair.

A process called Stress-Absorbing Fiberglass Layer of Emulsified Asphalt (SAFLEA) was used to allow crews to apply a seal-coat finish to the surface layer, extending the life of the roadway 5-10 years.

The interim treatment preserved the deteriorating surface, allowing additional time to pursue a more extensive project to address geometric design issues and pavement rehabilitation.

The interim treatment preserved the deteriorating surface, allowing additional time to pursue a more extensive project to address geometric design issues and pavement rehabilitation.

The SAFLEA treatment strengthens and reinforces a traditional sealcoat by sandwiching two-inch long chopped fiberglass strands between two layers of asphalt emulsion.

After the emulsion and strands are applied, chip seal aggregate is placed and rolled as normal. The reinforced surface slows cracking and resists snowplow damage. Although the technology is somewhat new to Idaho and surrounding states, it has been used successfully in Europe the past two decades.

Using the SAFLEA process on the 13.2-mile project cost only 20 percent more than a standard seal coat.

Published 10-7-2011