Unsecured wheel creates safety opportunity

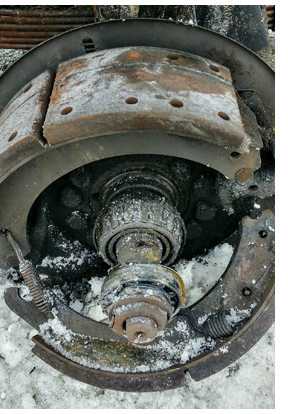

On Christmas Day, a wheel fell off an ITD plow truck in District 3, providing a test for recent changes to the accident investigation process that focuses on problem identification and resolution. The outcome of the investigation led to statewide changes to truck maintenance that will reduce risks to other employees and the traveling public.

The mishap could have had a very different outcome if the wheel had fallen off while traveling at plowing speeds.

Thankfully, the employee felt something was not quite right and pulled over to check it out. Luckily, the truck was almost completely stopped when the wheel fell off.

The mishap investigation highlights a shift in mindset for ITD to find the root cause of accidents and prevent them from happening, rather than punish the driver operating the equipment when the failure occurred.

“This is a great example of the new mishap investigation process and reporting, using root-cause analysis,” said ITD Safety Manager Randy Danner. “With our previous investigation process, this probably would have been identified as a preventable incident and the responsibility (blame) placed on the driver.”

In this case, the D3 team identified a gap in the Preventative Maintenance (PM) process, and recommended corrective action. Specifically, operators did not know they were required to check the wheel bearing oil bath.

To alleviate future incidents, the D3 team recommended this check be performed weekly or every 1,000 miles. The Maintenance Operations Steering Committee agreed, and the information is being shared across the department.

“I’m quite happy with this improved investigation process,” Danner said. “It emphasizes good corrective actions to help prevent future occurrences. We are making great strides in changing our investigation process into a positive activity.”

Published 03-02-18