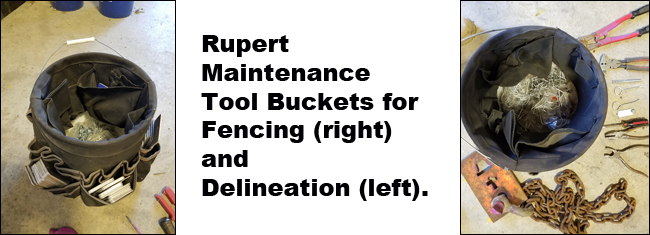

D4 creates tool bucket to expedite common maintenance tasks

![]()

Innovation does not have to be a brand-new, never-before-seen product or service. It can simply be using an existing product or method to improve your job. Such is the case with an idea out of District 4.

Fixing fencing, improving delineation, and repairing damaged guardrail on our state highways and interstates can take some time, especially if you lack the tools to take care of the task at that moment and are forced to return to the shed to get the appropriate gear before heading back to the site.

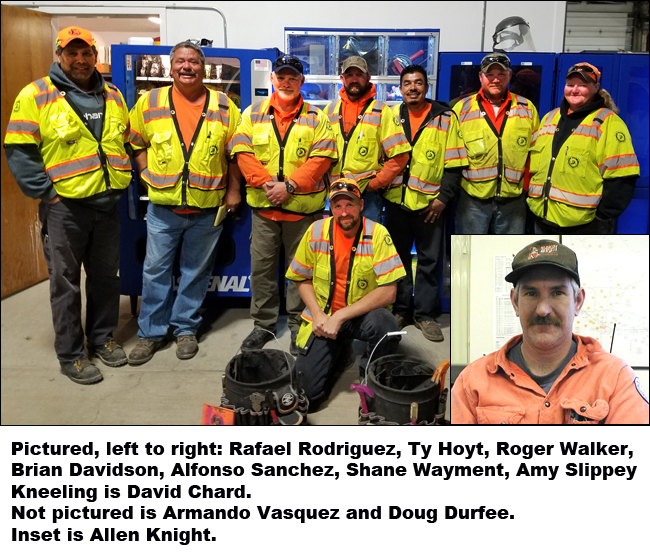

To alleviate this delay, D4's Allen Knight and the maintenance crew from the Rupert Maintenance shed came up with the idea of a tool bucket specific to these tasks containing all of the tools that would be needed to complete the job.

"The tool bucket came into play about two years ago when the crew wanted bags for fencing, delineation and a better bag for guardrail," said Knight. "We found these canvas inserts you put in a five-gallon bucket. It's grab-and-run, so to speak."

Knight said his crew made a specific bucket for guardrail repair, and saves about 80 hours per year, he estimates. He said carpenters and handymen also use them.

Knight said he pulled up a Transportation Asset Management (TAMS) report that shows the crews work on fence projects for 700 hours each year.

"The Tool Bucket keeps all tools in a container to carry along the fence line, so the employee does not have to go back to the truck to get another tool."

Published 09-28-18