District 2 shapes up some of its sheds

![]()

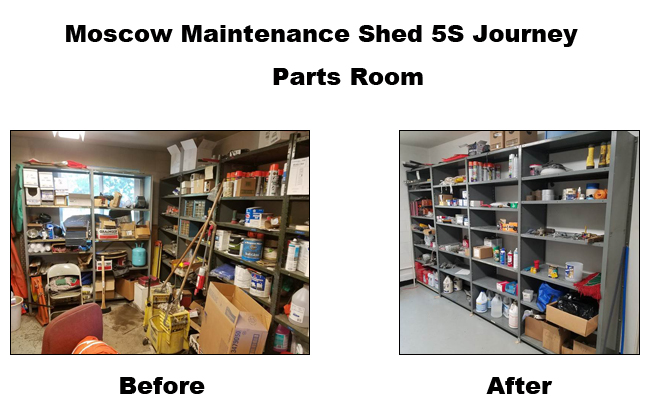

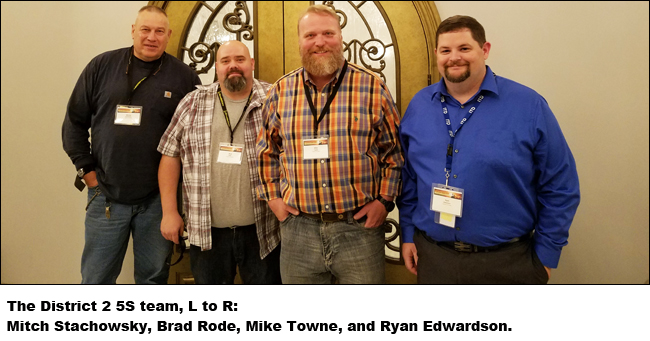

ITD volunteers came together this August to transform the Moscow and Kooskia sheds using the 5S process — sort, set in order, shine, standardize and sustain.

It is more than just another acronym. 5S takes on meaning to the crews who implement it. To them, it means better organization, increased efficiency, and boosted morale:

“It’s about separating the nonessential from the essential in your work area for improved operations,” said Mike Towne, one of the 5S leaders in D2.

Although its worldly origins aren’t as clear, 5S was first introduced to ITD at the 2016 Leadership Summit to see if the concept would take root. A single team of ITD employees from across the state orchestrated four-hour events coordinated at Craigmont, Blackfoot, Carey and Marsing sheds, though it was clear after these events that crews wanted more than just four hours.

After the summit was over, training was deployed to numerous work units across ITD and 5S happened at Aeronautics, the D1 Shop, more sheds and even in the back offices and the digital environments of IT.

In the second summit, a team came together to see what they could do in a single shed—in this case the Rupert shed—for an entire week instead of just a few hours.

This year, two organic teams sprung up. One cross-divisional team in D2 conquered the Moscow and Kooskia sheds, while another team of all frontline District 5 staff took on Pocatello, American Falls, Montpelier, Malad, and Soda Springs sheds.

Now, more than 15 ITD maintenance sheds or work areas have undergone a 5S event, including eight that took several days.

These events involve looking at doing things differently to benefit the work environment and crews’ efficiency.

“They take significant pre-planning, along with a change in the existing mindset, to be more than just spring cleaning,” said Jim Phillips, an ITD employee in Boise's Headquarters and an organizational-development specialist who serves as the main point of contact for the 5S process.

Towne explained that it is especially useful for new employees because they do not need to spend as much time learning where tools are stored. If sustained, it can also reduce frustration in the work place because everyone has ownership in where items are located and what conditions they are kept in.

As part of the process, several crews have developed innovations—ranging from a new oil delivery system to a snow plow blade rack and cart—as they rethink the old way of getting the job done.

The Kooskia shed transformation featured a chainsaw rack designed by Toby Thibert and Jasun Walker with help from Josh Allen in the Lewiston shop. The innovative rack stores all gear, oil and chainsaws above a drip tray lined with an absorbent pad.

“Ultimately, 5S is something we’d like to see done in every shed, office and digital environment because the process typically has a positive effect,” Phillips said. “It’s been gratifying to see sheds make these changes.”

ITD Chief Administration Office Char McArthur had more to say: “5S is foundational to our efforts to make sure employees are safe on the job and have the tools they need to do their work where they need to do it. It is not an activity that can be undertaken or sustained without a solid team. It takes a committed team who wants to work in a better way and is willing to help achieve that goal. That is what we are seeing happen across the state, team after team. It’s like watching the snow line slowly recede after the winter.”

Published 11-30-18