Leadership Summit team assesses snowplow blades

![]()

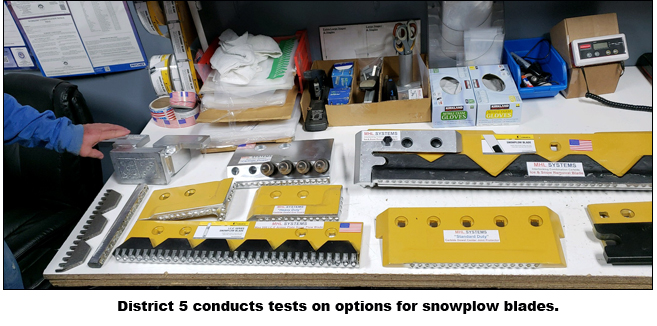

The District 5 Equipment Assessment team tackled a common problem at October’s Leadership Summit — determining which piece or brand of equipment is most cost effective and produces the best results.

Another equally important aspect to consider is the impact on safety. Ease of use and difficulty of equipment changeovers also were considered.

Their goal was twofold: To develop and test a model that allowed frontline staff to have input into equipment and tool purchases, and that can be replicated to other types of equipment/tool decisions statewide.

VIDEO: Check out Gil Wright's opening pitch at the summit.

“Director Brian Ness and the senior leaders want to change ITD culture to allow decisions to be made closer to the frontline,” explained Soda Springs Maintenance Foreman Gil Wright, who served as the team leader. “However, frontline employees have said they feel they have no input on decisions being made.

“So, when an opportunity came up to form an equipment analysis team in District 5, I remembered the Director’s words and volunteered to lead this effort to give employees a voice. I asked for a volunteer from each foreman area, to be on the team.”

The team tested three types of snowplow blades All eight maintenance sheds in District 5 participated in the study.

“A salesman representing Razor XL winter blades came out and told us how good their blades were,” said Wright. “So we decided to check.” Over the course of the 2017 winter season, the team gathered data from thousands of miles of blade use.

In the end, the team found that Valk had a cost-per-mile of 71 cents, Interlock was next at 83 cents per mile, and Razor came in at $1.12 per mile. However, the lower cost didn’t automatically carry the day.

“The blade that we have used in the past that the operators liked is called the interlocker blade by MHL from Salt Lake,” said Wright. “They outlasted all of the other blades in testing. They have a wear indicator, which is a big help for our operators, as it makes it a lot easier to check to see if your blades need changed.”

The cost was a little higher, but, with the wear indicator and them lasting the longest, we felt this was the best system overall.”

Testing continues. The least expensive were the double Valk blades, so operators are using existing supplies of these blades to compare against new blades currently under contract.

The ITD team also met with crews from Utah and Wyoming departments of transportation about their blade use, and they hope to meet with a Montana contingent soon.

At the summit, Wright said, “We are here to share our journey of frontline employees developing data-driven input into the selection and use of snowplow blades. We believe that frontline folks can and should be involved in the decisions that affect their work the most.”

“I want everyone to know if they would like to see what we are doing, we would like to meet with other districts to chat or exchange ideas."

Published 01-11-19