D3’s Dew and Kriebs come up with method to

“perfectly square up” bases on posts

![]()

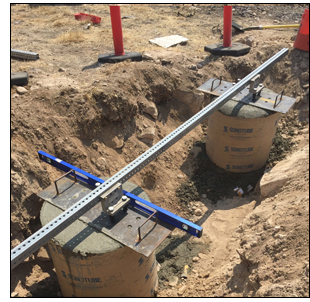

Talk about precision work.

If there is even the tiniest difference between the anchor holes on a steel breakaway post, the posts do not mount perfectly straight, which affects not only the position and display of the sign, but also the effectiveness of the safety features should the post be hit.

To combat this, D3’s Josh Dew and Doug Kriebs came up with a way to perfectly square up bases for breakaway posts on multi-post signs when pouring concrete — quickly, easily, and to perfect measurement every time.

“When installing bases for multi-post breakaway signs (steel posts), we currently use two separate metal plates with holes to attach the anchors to lower into the concrete tubes when pouring the concrete,” Dew explained. “The bases can be as far as nine feet apart from each other, making it a challenge to perfectly align the anch ors so that the feet of the posts mount perfectly for easy and accurate sign installation. If the anchors are even an 1/8 of an inch off between bases, it can make mounting the posts perpendicular to one another an almost impossible task.”

ors so that the feet of the posts mount perfectly for easy and accurate sign installation. If the anchors are even an 1/8 of an inch off between bases, it can make mounting the posts perpendicular to one another an almost impossible task.”

There are square metal sign post for most signs. By mounting metal plates that attach at the base of the pole and to anchors in the concrete, a worker can securely mount the feet at the desired width, then mount the metal plate and anchors to the feet, and set both anchors into the concrete bases at the same time and both are perfectly aligned with one another.

“We came up with the idea and built the ‘jig’ when we had to pour foundations for the Veterans Memorial I-84 highway signs in the summer of 2017. We came up with this idea after we spent almost an entire day drilling new holes in the foundations for the anchor bolts because using a level and string line in an attempt to align the templates on both foundations didn’t work.” Dew explained.

The holes in the bar are perfectly drilled so that the sign post anchor plates (circled in the picture) can be adjusted in or out for signs requiring smaller or wider base widths which allows this one prototype to be used for any size of dual-leg sign that ITD uses on its roadways.

Dew estimates a few hours of time savings, a cost savings because workers would not need to rent a drill-and-bit set from a local company, and a quality improvement because both templates perfectly align with the anchor bolts, eliminating the headache of having to re-drill holes in the foundation.

“This allows for perfect post and sign installation every time, and it takes the time out of running a tape measure back and forth from one end of the plate tothe other several times and/or pushing the plate back and forth or side to side — no more "eye balling" in an attempt to get it right,” Dew said.

Published 02-22-19