Keeping our wings lit

![]()

After another winter of fierce weather and plows working around the clock, crews and equipment have been put to the test. Never-ending storms also seem to keep the work we do present in the eyes of the public.

Operators often worry that the public doesn’t see them, or more specifically, their wing plows. ITD has routinely upgraded and explored various lighting methods to keep operators and equipment visible.

An innovation from longtime Potlatch operator Lonnie Crume supports those efforts. He plows with a junior wing, which allows him to pull it in and out while it’s down on the road. Because it is extendable, it experiences significant vibrations that can wear out the wiring for the light on the end.

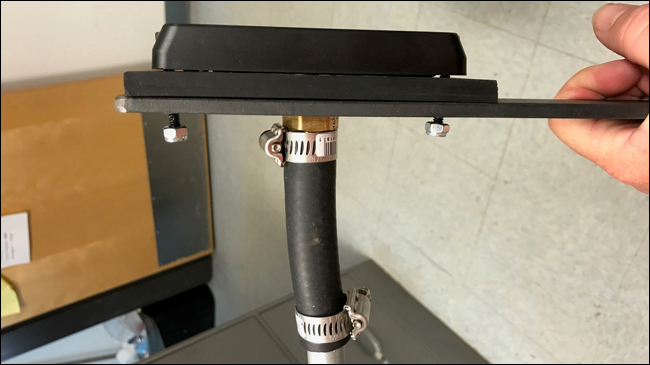

Crume took a tube, sealed the light’s wires, and made a rubber bracket to mount it to the plow that absorbs the vibrations better.

“We were losing lights on the junior wings sometimes within a day of installation,” Crume said. “I put together some odds and ends we had at the shed and tried something new.”

When hooking up the new light, Crume also adds a loop of the encased wiring where it mounts to the wing so if the bolt breaks the wires have enough slack to stay intact.

“The new system seems to prolong the life of the light, and the loop prolongs the wiring,” Crume said. “The lights still fail but at least last a season rather than a couple days or weeks.”

Given that each replacement costs $100 in parts plus more in labor, this simple idea means worthwhile savings for the crew and ultimately taxpayers.

Published 03-29-19