Pre-wet system modification

saves thousands during North Idaho winter

![]()

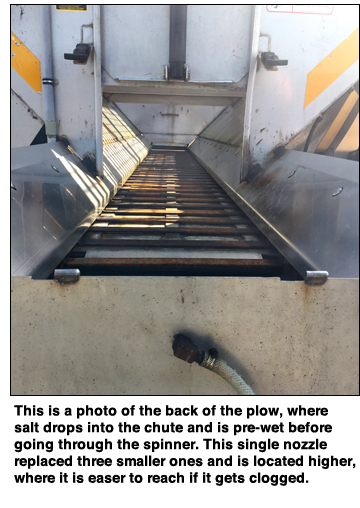

Pre-wetting solid salt with liquid salt brine before dropping it onto the road helps the application stick and be more effective. It’s one way ITD optimizes snowfighting efforts.

Until this year, the pre-wet system featured on D1 plows used multiple nozzles and a flow meter to soak the salt and track its usage out on the highways. However, when clogs inevitably formed in the three small nozzles included in the original system, pressure built up and often ruptured the glass frame of the flow meter. Once that blew out, the whole pre-wet system shut down.

“We usually have a 75% failure rate for the flow meters each season,” shop superintendent Dustin Chase said.

At $462 apiece, that’s not an inexpensive part to replace, especially if a mechanic has to travel to fix it. Back in September, the shop decided to try out some changes as they were converting trucks.

“We switched out the three small nozzles with one bigger nozzle to reduce plugging, and we moved the flow meter from the pressure side of the system to the suction side,” Chase said.

Mechanic Pete Lenz experienced the difference himself this winter.

“You always have to replace one here and there, but they didn’t give us nearly as much trouble as normal,” said Lenz.

Though the numbers aren't fully crunched yet, around $18,000 in parts and 120 hours in labor is expected to have been saved in reduced flow meter replacements.

Published 04-12-19